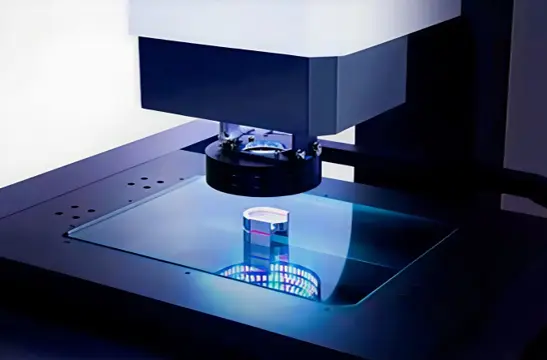

The Science Behind Non-Contact Optical Measurement in Video Measurement Systems (VMS)

Non-contact optical measurement refers to the acquisition of dimensional and geometric data without physically touching the measured component. Instead of mechanical probes, these systems rely on controlled illumination, precision optics, and digital imaging to extract measurable information from reflected or transmitted light. As manufacturing tolerances continue to tighten and component geometries become increasingly intricate, traditional […]

Introduction to Industrial Metrology: Why Measurement Matters in Manufacturing

Modern manufacturing is built on the expectation that components will function reliably under demanding operational conditions. From semiconductor devices inside digital systems to precision mechanical assemblies in industrial equipment, product performance depends heavily on how accurately design specifications are translated into physical reality. To maintain dimensional accuracy throughout production, industrial metrology systems are integrated directly […]

Boosting Productivity in High-Volume Manufacturing with Automated VMS

High-volume manufacturing requires fast output, stable quality, and consistent accuracy. As production increases, even minor delays or inconsistencies in inspection can create bottlenecks and increase costs. Many factories face this challenge when relying on manual measurement tools, which are slower, operator-dependent, and difficult to scale. To solve this, manufacturers are increasingly adopting Automated Video Measurement […]

How an Automotive Supplier Reduced Defect Rates with CMM

In automotive manufacturing, even small defects in components can lead to serious issues, from assembly problems and production delays to increased costs and safety risks. Ensuring that every part meets exact specifications is essential for quality, reliability, and customer trust. Traditional inspection methods, such as gauges or visual checks, often miss subtle deviations or lack […]

Improving Metal Stamping Quality with High-Precision Measurement

Metal stamping is a fundamental process in modern manufacturing, widely used in automotive, electronics, medical devices, and consumer products. As products become more complex and manufacturing tolerances tighter, the demand for high-quality stamped parts has grown significantly. Even minor defects, such as burrs, dimensional variations, warping, and misalignment, can lead to production delays, higher costs, […]

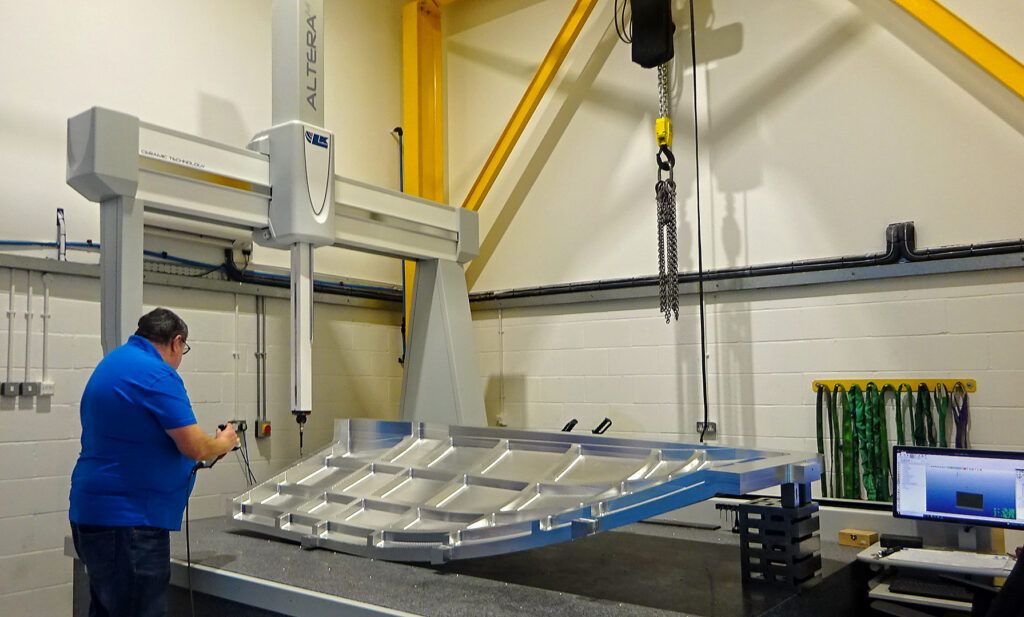

Why Aerospace Manufactures Choose High Precision Measurement Systems

In the aerospace industry, precision is everything. Each part from turbine blades to fuselage panels must operate flawlessly under extreme stress, pressure, and temperature.To achieve this, aerospace manufacturers depend on high-precision measurement systems such as Video Measuring Systems (VMS), Coordinate Measuring Machines (CMM), and 3D Scanners to verify accuracy down to the micrometer. These technologies […]

Ensuring Reliable Quality Control in the Automotive Industry with VMS and CMM

In today’s competitive automotive industry, reliable quality control is one of the main pillars of successful manufacturing. Every component from engine parts to precision electronics must meet strict dimensional and functional requirements. Even a small deviation can lead to performance issues, safety risks, or production delays.To prevent this, automotive manufacturers rely heavily on advanced metrology […]

The Role of CMM in Automotive and Aerospace Quality Control

In high-precision industries like automotive and aerospace, quality control is not just a step in production it’s the foundation of safety, reliability, and brand reputation. Every part, no matter how small, must meet exact dimensional specifications. That’s why Coordinate Measuring Machines (CMMs) have become a critical part of modern manufacturing. CMMs allow engineers and […]

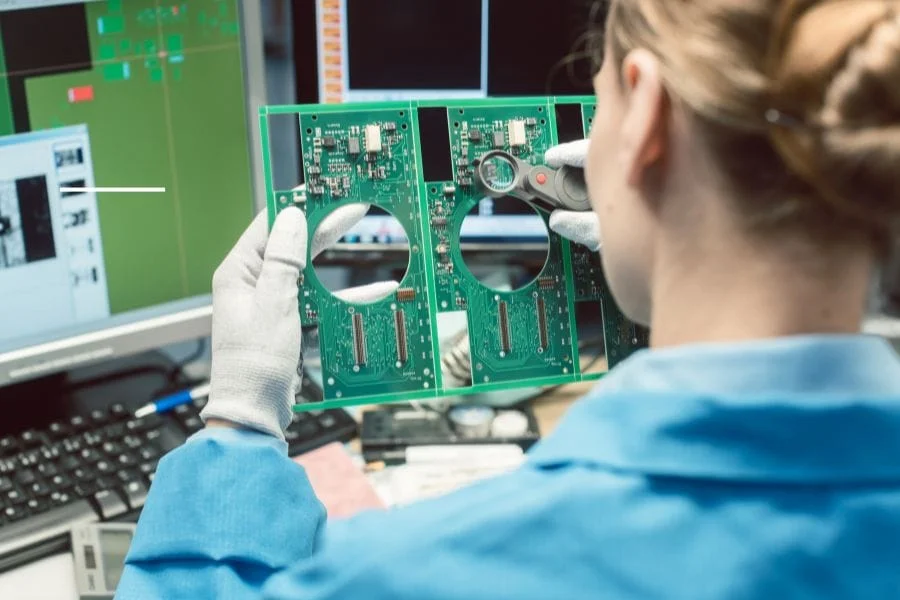

Improving Electronics Quality Control with Precision Measurement

In the rapidly advancing world of electronics manufacturing, every micron matters. From high-speed processors to automotive sensors, even the smallest dimensional error or hidden defect can lead to product malfunction, data loss, or safety hazards. That’s why precision measurement has become the foundation of quality control (QC) ensuring every part, circuit, and assembly performs exactly […]

2D vs 3D X Ray Inspection: Understanding the Key Differences

X-ray inspection has become an essential part of non-destructive testing (NDT) in industries such as electronics, automotive, aerospace, and medical devices. As products become smaller, more complex, and more precise, manufacturers need reliable ways to detect hidden defects without damaging the item. Two of the most common techniques are 2D X-ray inspection and 3D X-ray […]

Quality Control in Electronics: Measuring Tiny Components – Challenges and Practical Solutions

The electronics industry is constantly evolving. Devices are becoming more compact, lighter, and faster — yet their reliability depends on components that are almost invisible to the naked eye. From semiconductor chips and sensors to connectors and surface-mounted devices (SMD), the demand for micron-level accuracy is higher than ever. Quality control (QC) in this […]

Why Non-Contact Measurement is Ideal for Fragile Components in Manufacturing

Manufacturing today demands precision, efficiency, and consistency. But when the components being inspected are fragile like semiconductor wafers, medical devices, thin glass, or lightweight composites — traditional contact-based measurement methods fall short. Probes, calipers, and touch CMMs risk damaging parts or giving distorted results. This is why non-contact measurement systems have become the preferred solution. […]

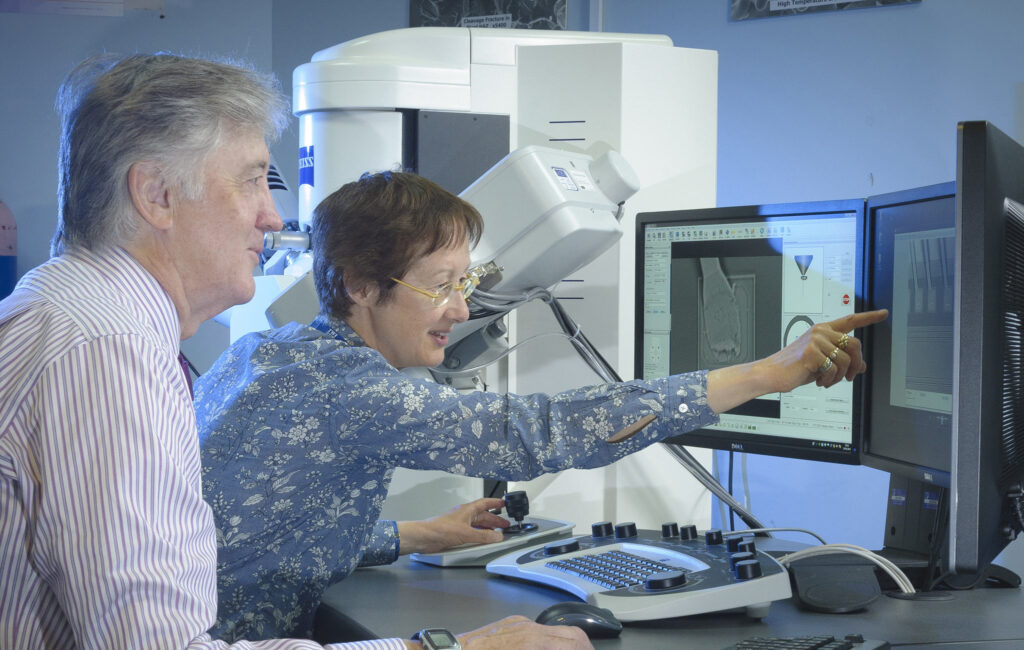

Top Applications of SEM in Electronics and Semiconductor Production

The electronics and semiconductor industry is built on precision. As chips and devices continue to shrink into the nanometer range, manufacturers need tools that can see, measure, and analyze features too small for the human eye. Scanning Electron Microscopy (SEM) is one of the most powerful solutions for this challenge. SEM provides ultra-high-resolution imaging, nanoscale […]

Why Precision Inspection is Essential in Medical Device Manufacturing

Medical devices must meet the highest standards of quality and reliability. A minor defect in a surgical instrument, implant, or catheter can endanger patient safety and trigger costly recalls. This is why precision inspection is not optional it is a core requirement in medical device manufacturing. Advanced inspection technologies provide manufacturers with accurate, repeatable, and […]

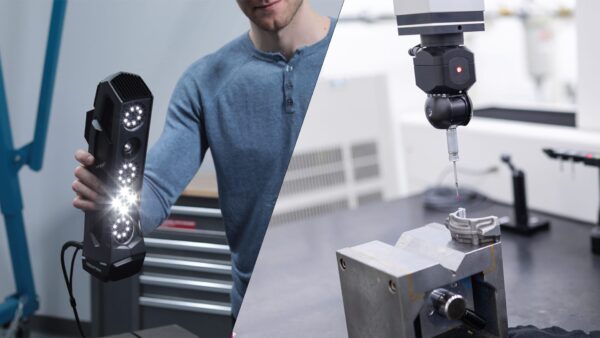

Contact vs Non-Contact Measurement: Choosing the Right Method

Quality control is the backbone of modern manufacturing. A minor dimensional error in a component can lead to assembly issues, product malfunctions, or costly recalls. Traditional tools such as calipers and micrometers remain valuable, but they cannot always meet the speed, accuracy, and complexity demands of today’s production environments. To address these challenges, manufacturers rely […]