From traditional vehicles to new energy vehicles, from powertrains, auto parts to body and sub-assembly, from inspections in measurement rooms to automated production line inspections, from single size evaluation and analysis to full-process data management systems, Metrology provides a comprehensive detection solution for automobile manufacturers.

Detection elements:

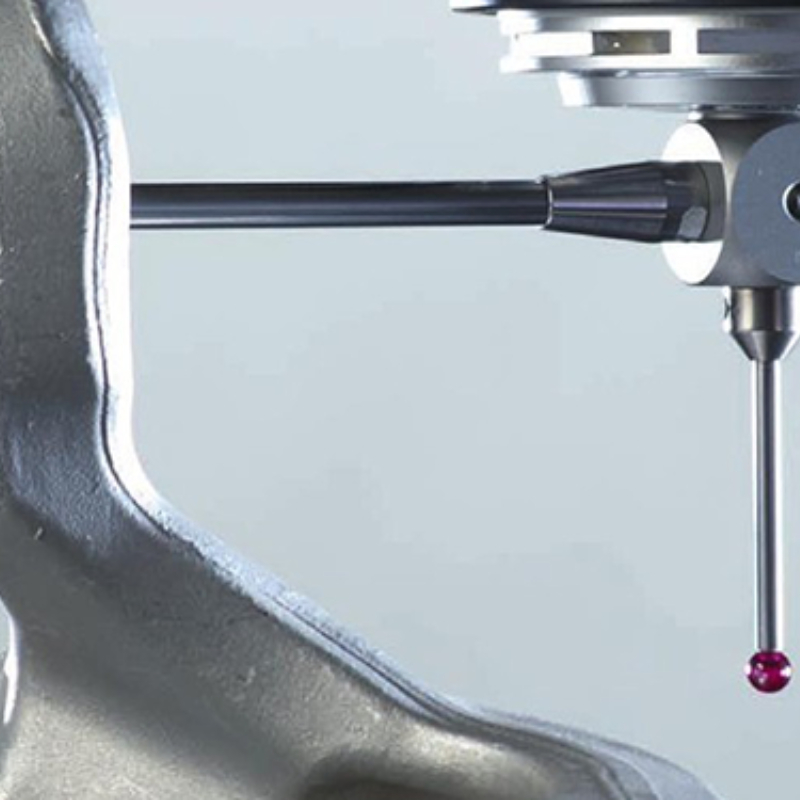

Provide high-precision measurement for various transmission components: cylinder block, cylinder head, gearbox, crankshaft, camshaft.

Detection elements:

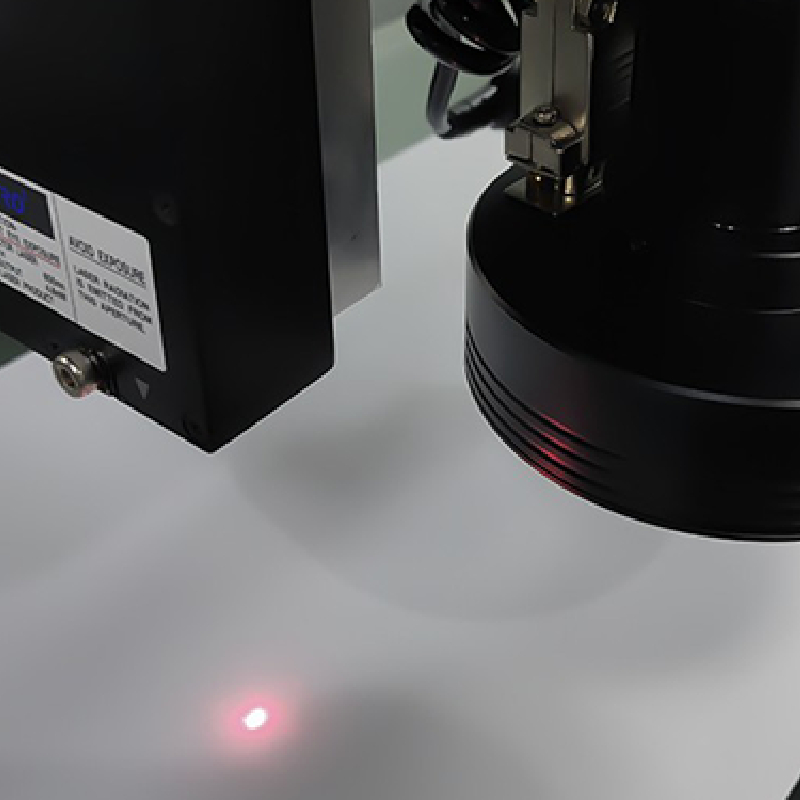

With the help of infrared or optical scanning measurement technology, the car elbow is measured in a non-contact form, and the professional analysis and evaluation are further completed with the help of advanced software technology.

Detection elements:

Use the flexible articulated arm scanning system to accurately obtain the shape and size of automotive interior parts. The scanning speed is fast, the point cloud quality is high, and the complex surface can be measured with high precision.

Detection elements:

Utilize the blue light camera measurement system to collect massive data, match and optimize the body and interior and exterior trim parts to ensure the dimensional accuracy and appearance quality of the whole vehicle

Detection elements:

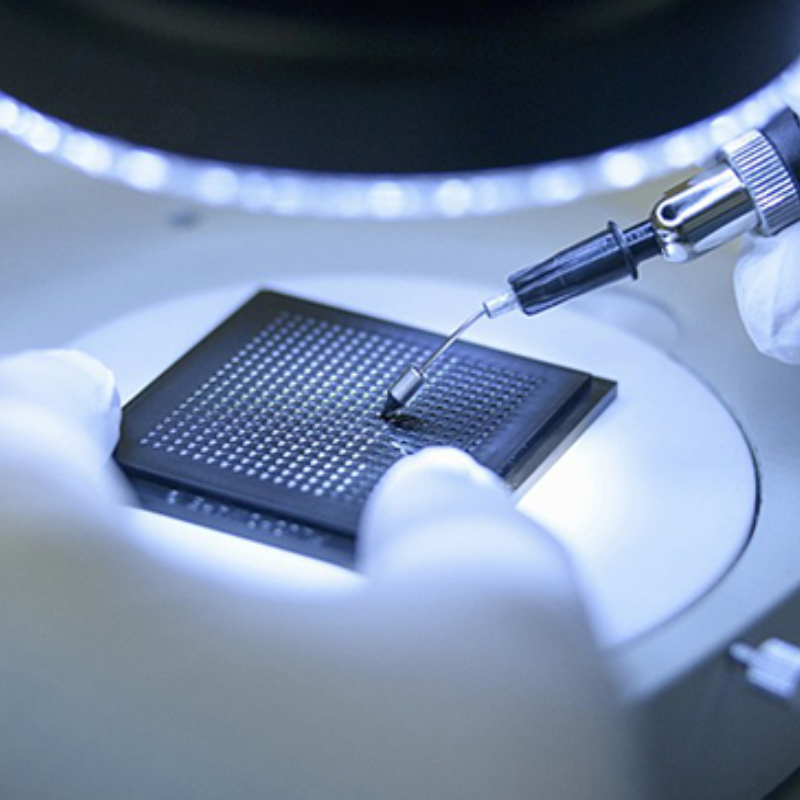

Automotive electronic components are small in size and complex in features. A high-end composite image measuring instrument is used to combine trigger, optical, DCC and confocal white light sensors to complete the measurement of all the characteristics of complex electronic components.

Detection elements:

The cantilever machine is used for contact or scanning measurement, equipped with a 360° infinite wrist and laser probe, which is flexible and efficient. Automatic measurement can also be realized by using AGV intelligent vehicle and RFID.

Detection elements:

Combine raster scanning technology with flexible robot performance to realize functions such as interactive scanning planning, robot path generation and anti-collision system, greatly improving detection efficiency

Detection elements:

Using NEXTSENSE’s laser light section technology, the gap and face difference of the car can be measured from different angles, the inner edge of the gap can be measured, and the tilt correction can be performed in real time.

Mainly used for 2D size detection, suitable for quick measurement of small parts size and features

Various types of stylus can be configured to perform three-dimensional spatial inspection of products

Used for part height and flatness measurement, measurement speed is faster than optics and foundation, non-contact measurement

Used for part height, flatness and profile measurement. Higher accuracy, less than 1μm, faster scanning speed, smaller spot diameter, measurement of bright or transparent surfaces

Welcome to Hansvue Metrology We are a leading supplier of quality control and metrology equipment in Malaysia

Copyright 2024 © HansVue Metrology

WhatsApp us