Blog Posts

The latest updates, insights, and expert advice on all things related to our industry. Explore our articles to stay informed and inspired.

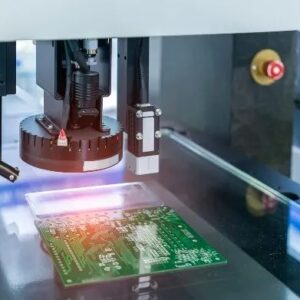

2D vs 3D X Ray Inspection: Understanding the Key Differences

X-ray inspection has become an essential part of non-destructive testing (NDT) in industries such as electronics, automotive, aerospace, and medical devices. As products become smaller, more complex, and more precise,…

Boosting Productivity in High-Volume Manufacturing with Automated VMS

High-volume manufacturing requires fast output, stable quality, and consistent accuracy. As production increases, even minor delays or inconsistencies in inspection can create bottlenecks and increase costs. Many factories face this…

CMM vs VMS: Which Measuring System Is Right for Your Factory?

Precision measurement is essential in modern manufacturing. Even the smallest deviation can result in poor product quality, production delays, or costly rework. While traditional measuring tools like calipers and gauges…

Common Measurement Challenges in Different Industries

Metrology plays a critical role across various industries, ensuring that components meet strict quality and precision standards. However, different industries face unique measurement challenges due to their specific requirements and…

Contact vs Non-Contact Measurement: Choosing the Right Method

Quality control is the backbone of modern manufacturing. A minor dimensional error in a component can lead to assembly issues, product malfunctions, or costly recalls. Traditional tools such as calipers…

Ensuring Reliable Quality Control in the Automotive Industry with VMS and CMM

In today’s competitive automotive industry, reliable quality control is one of the main pillars of successful manufacturing. Every component from engine parts to precision electronics must meet strict dimensional and…

How an Automotive Supplier Reduced Defect Rates with CMM

In automotive manufacturing, even small defects in components can lead to serious issues, from assembly problems and production delays to increased costs and safety risks. Ensuring that every part meets…

How is Video Measurement Machine important in Electronics and Semiconductor Industry?

In the fast-paced and highly precise world of electronics and semiconductors, the demand for accuracy in manufacturing has never been greater. As devices become smaller and more powerful, the need…

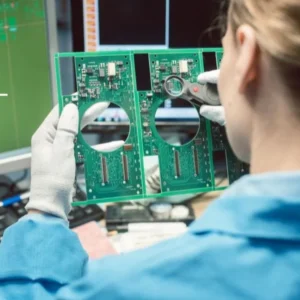

Improving Electronics Quality Control with Precision Measurement

In the rapidly advancing world of electronics manufacturing, every micron matters. From high-speed processors to automotive sensors, even the smallest dimensional error or hidden defect can lead to product malfunction,…

Improving Metal Stamping Quality with High-Precision Measurement

Metal stamping is a fundamental process in modern manufacturing, widely used in automotive, electronics, medical devices, and consumer products. As products become more complex and manufacturing tolerances tighter, the demand…

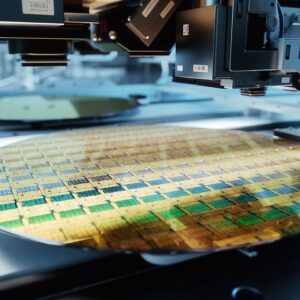

Inspection of Semiconductors and Electronics with Video Measurement Machine System

Video measurement systems play a crucial role in both the semiconductor and electronics industries, enhancing quality control, manufacturing efficiency, and product reliability. Here’s a combined summary of their applications Defect…

Quality Control in Electronics: Measuring Tiny Components – Challenges and Practical Solutions

The electronics industry is constantly evolving. Devices are becoming more compact, lighter, and faster — yet their reliability depends on components that are almost invisible to the naked eye. From…

The Role of CMM in Automotive and Aerospace Quality Control

In high-precision industries like automotive and aerospace, quality control is not just a step in production it’s the foundation of safety, reliability, and brand reputation. Every part, no matter how…

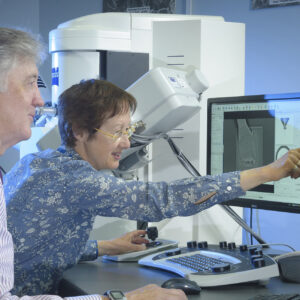

Top Applications of SEM in Electronics and Semiconductor Production

The electronics and semiconductor industry is built on precision. As chips and devices continue to shrink into the nanometer range, manufacturers need tools that can see, measure, and analyze features…

What is a Video Measurement System?

BASIC Video Measurement Systems, also sometimes known as optical co-ordinate measuring machines, are specially designed for precision dimensional measurements of small parts. The measurements are purposely done offline to minimize…