Description

An advanced non-destructive component counting solution designed for high-volume electronics manufacturing and inventory control. Built on proven X-ray imaging technology, the CX7000 delivers fast, precise, and reliable counting of SMD components directly on tape and reels without unwinding, significantly improving efficiency compared to traditional manual or optical counters.

Key Features & Capabilities

-

High-Speed X-Ray Counting: Delivers rapid component counts in under ~10 seconds per reel for typical 7″–17″ sizes, dramatically reducing labor time.

-

Non-Destructive Inspection: Uses high-resolution X-ray imaging to count components without risk of damage or loss, preserving tape integrity.

-

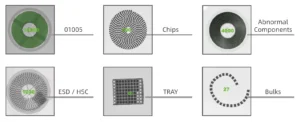

Exceptional Accuracy: Provides industry-leading counting accuracy up to ≥99.99% across a wide range of component types and sizes, including ultra-small 01005 parts.

-

Wide Compatibility: Supports multiple reel sizes (typically 7″–17″) and a broad variety of discrete components such as resistors, capacitors, transistors, diodes, crystals, and more.

-

Integrated Data Connectivity: Seamlessly links with ERP, MES, WMS and other smart storage systems for streamlined inventory management and traceability.

-

User-Friendly Operation: Intuitive interface and one-button counting operation require minimal training; advanced models include barcode scanning, label printing, and optional fingerprint access control.

-

Safety & Compliance: Fully shielded X-ray cabinet design ensures emissions well below international safety standards (typically <1 μSv/h), meeting FDA CDRH and global regulations.

Technical Highlights

-

X-Ray Source & Detector: Sealed X-ray tube with high-resolution flat panel detector (FPD) providing detailed imaging and reliable counting.

-

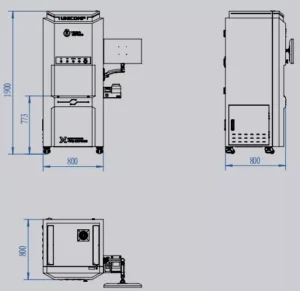

Inspection Area: Large effective detection area suitable for a variety of component and reel sizes.

-

Computer & Software: Industrial PC platform with Windows-based interface, facilitating quick analysis and data export.

-

Performance: Combines high frame rate imaging and powerful counting algorithms to deliver rapid throughput and precise results.

Applications

Ideal for electronics manufacturing, semiconductor assembly, quality control, incoming inspection, and warehouse inventory management, the CX7000 enhances operational efficiency across production lines and distribution centers by automating the counting process and reducing human error.