DESCRIPTION

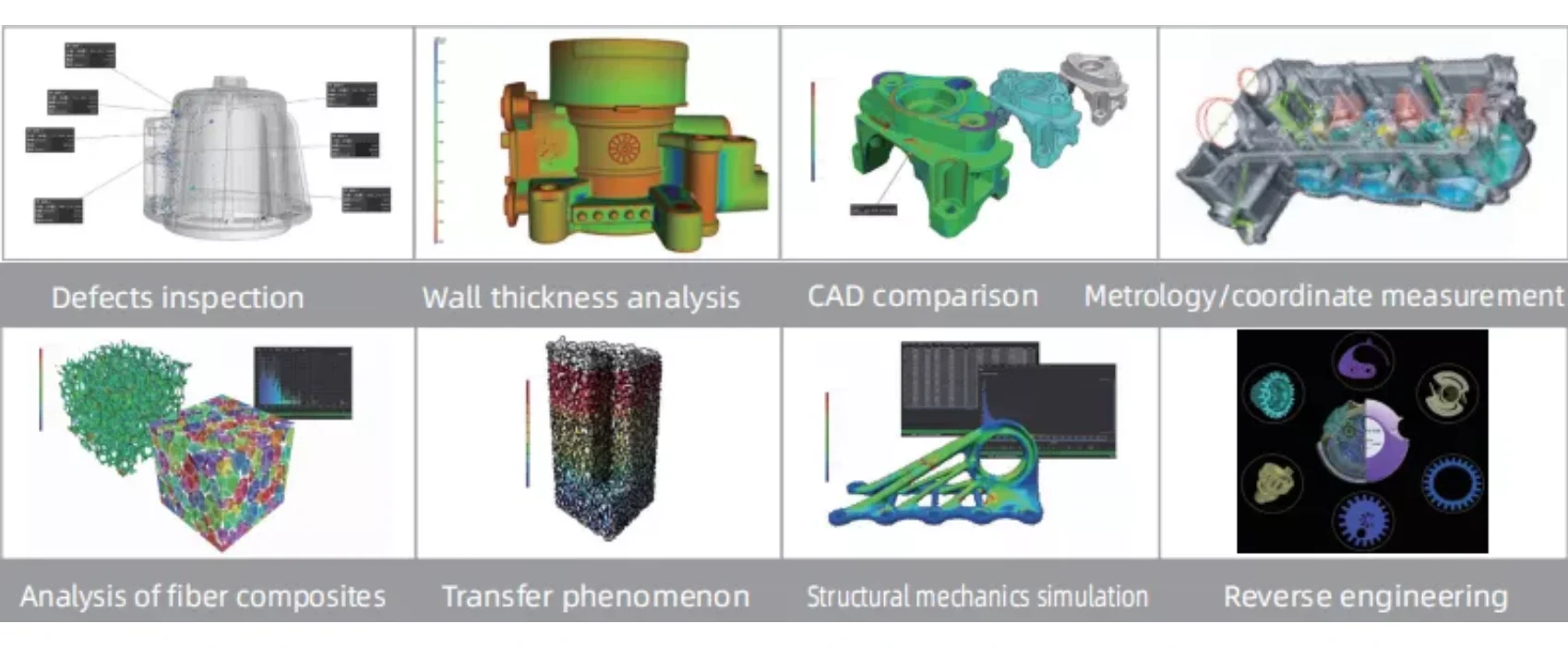

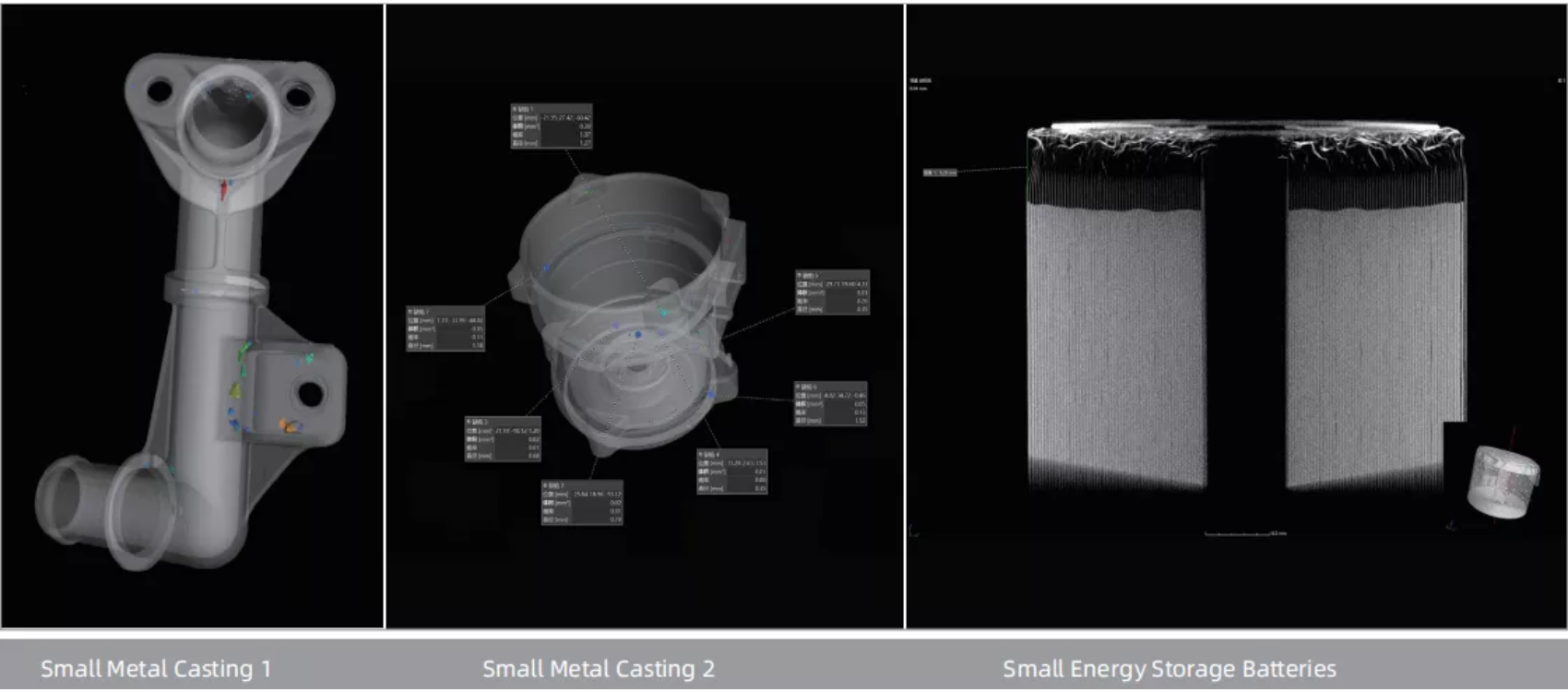

The UNCT3100 Industrial CT Testing System is a cutting-edge 160 kV computed tomography (CT) machine designed for precision non-destructive testing (NDT) across multiple industries. With dual imaging capability (DR + CT) and advanced 3D reconstruction, it offers deep internal inspection of components such as metal castings, non-ferrous parts, lithium battery cells, electronic assemblies, composite materials, geological samples, and more.

Key features include:

-

Dual DR & CT imaging: Switch between 2D radiography and 3D tomography modes for flexible inspection workflows.

-

High resolution & large detection range: Effective detection area ~ 427 × 427 mm, maximum scanning volume φ500 × 500 mm, with fine detail resolution capabilities.

-

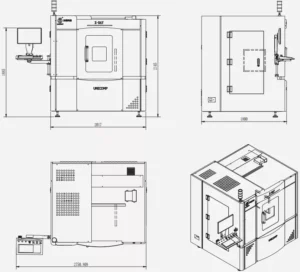

Compact footprint with strong performance: System dimensions ~ 1600 × 1040 × 1830 mm (L × W × H), power consumption ~ 9 kW.

-

User-friendly control & automation: The control system is designed for easy operation; users can master its basic functions with minimal training.

-

Safety & regulatory compliance: The system is engineered with multiple safety measures and maintains radiation dose levels substantially below national standards.