Description

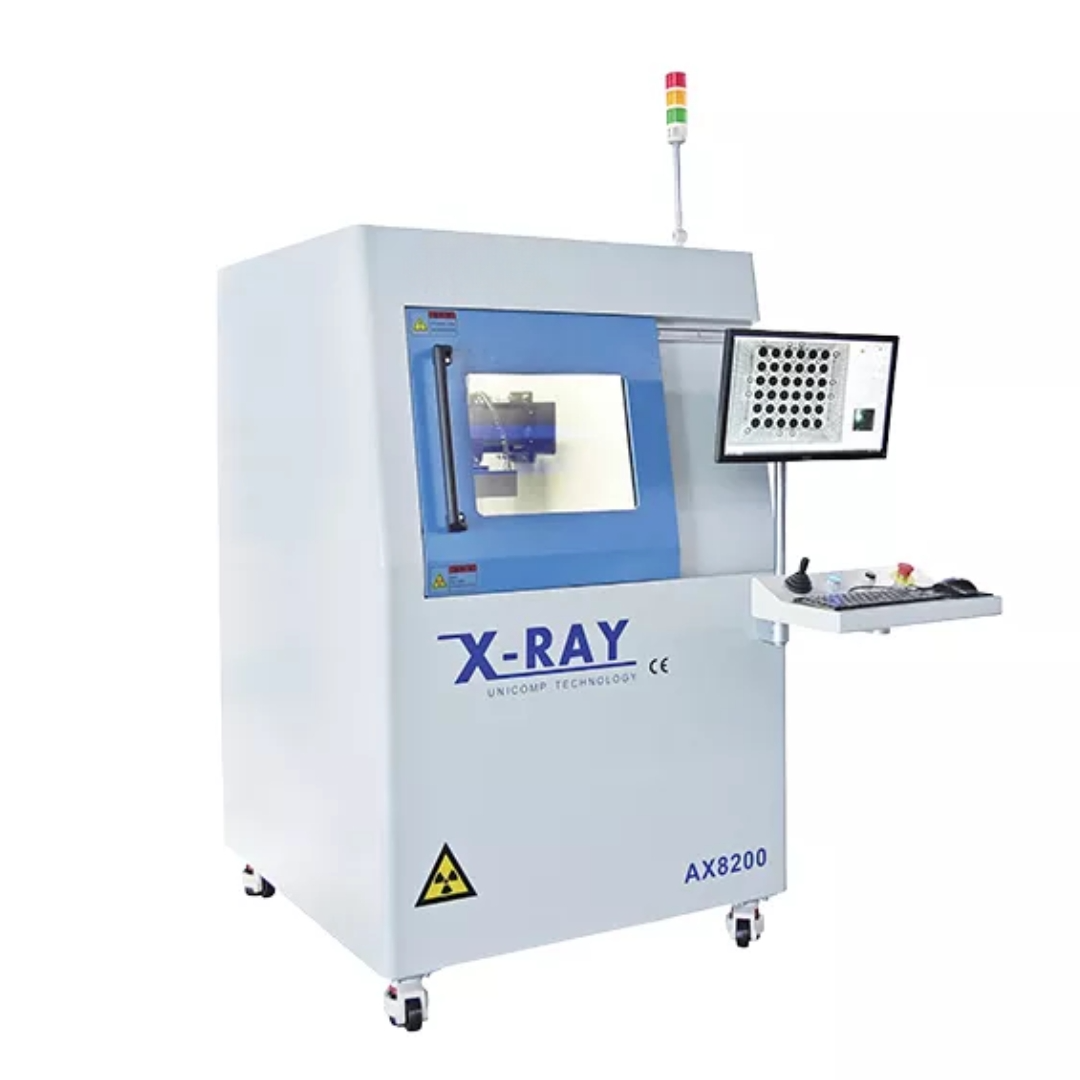

X-Ray Inspection Equipment AX8200 is a powerful and versatile non-destructive X-ray imaging system engineered for advanced inspection, defect analysis, and quality control across electronics manufacturing and other high-precision industries. It combines high-resolution imaging, flexible motion control, and automated measurement tools to support complex inspection tasks with exceptional accuracy and reliability.

Key Features & Capabilities

High-Resolution X-Ray Imaging

-

Equipped with a sealed X-ray tube up to 90 kV and a fine focal spot (~5 μm) for detailed imaging of internal structures.

-

Capable of magnification up to 600× to reveal subtle defects, solder voids, wire connections, and material inconsistencies.

Sophisticated Imaging & Measurement Software

-

Built-in tools support automatic measurement of BGA solder voids and multiple geometric parameters (distance, angle, diameter, polygon shapes, PTH fill rate).

-

CNC-programmable inspection routines streamline repeated inspections and enhance workflow efficiency.

-

Real-time display of voltage, current, angle, date, and imaging status.

Intelligent Motion & Control System

-

Five-axis motion manipulator (X/Y/Z1/Z2/T) with joystick, keyboard, and mouse control enables precise positioning and oblique views up to ±60° for comprehensive inspection angles.

-

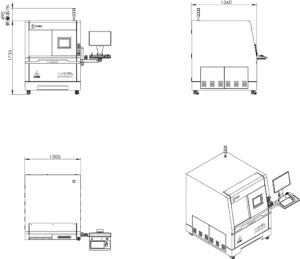

Large working area supports inspection of components and assemblies with maximum loading up to approximately 510 × 420 mm and inspection area near 435 × 385 mm.

Industrial-Grade Computing & Display

-

Industrial PC runs Windows 10 64-bit OS with Intel i7 processor, 8 GB RAM, and 1 TB storage for stable performance.

-

High-definition LCD display (typically ~22″) provides clear visual feedback and inspection visuals.

Safety & Operational Efficiency

-

Integrated electromagnetic interlocks and warning lights ensure operator safety.

-

X-ray auto-shutdown after inactivity reduces energy consumption and leakage remains well below international safety limits (<1 μSv/h).

-

Mounted on wheels for optimized mobility within lab and production environments.

Applications

The AX8200 is ideal for inspecting a wide range of items and materials, including but not limited to:

-

Lithium battery assemblies, including detection of polar solder joint defects and coiled battery casing anomalies.

-

PCB assemblies & semiconductor packages such as BGA, CSP, LED, flip-chip, and QFN.

-

Electronic modules and connectors, aerospace components, small metal cast parts, and photovoltaic materials.

-

Specialized industrial inspection where internal defects or structural integrity assessment is critical.