Metal stamping is a fundamental process in modern manufacturing, widely used in automotive, electronics, medical devices, and consumer products. As products become more complex and manufacturing tolerances tighter, the demand for high-quality stamped parts has grown significantly.

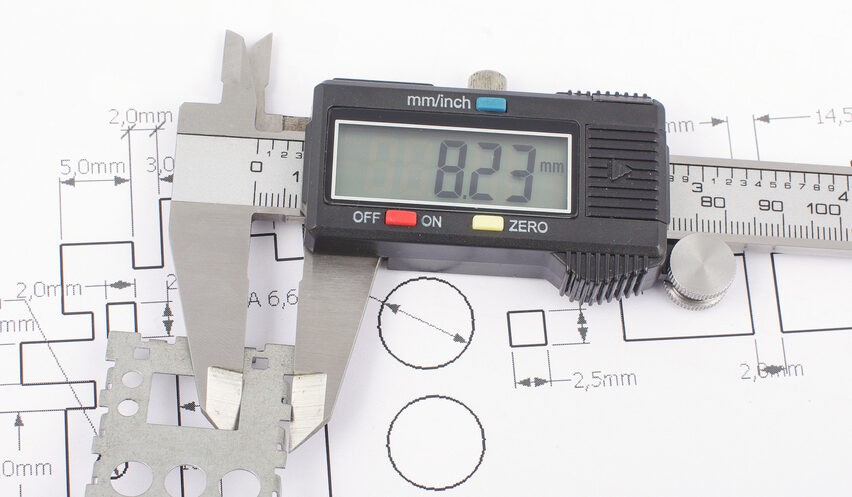

Even minor defects, such as burrs, dimensional variations, warping, and misalignment, can lead to production delays, higher costs, and quality complaints. In today’s competitive environment, maintaining consistent quality is critical. Manufacturers increasingly rely on high-precision measurement equipment, including Coordinate Measuring Machines (CMM), Video Measuring Systems (VMS), and 3D scanners, to ensure every part meets specifications, reduces waste, and improves operational efficiency.

Why Precision Measurement is Important in Metal Stamping

Metal stamping involves cutting, forming, and shaping metal sheets at high speed. Small inconsistencies in the process can cause significant defects, impacting both functionality and aesthetics of the final product. High-precision measurement provides several advantages:

1. Control Dimensional Accuracy:

Parts often need to fit precisely in assemblies. Measurement equipment ensures critical dimensions such as hole diameters, edge distances, and flatness remain within tight tolerances.

2. Detect Early Tool Wear

Punches and dies gradually wear out. Without proper monitoring, worn tools can produce defective parts. Precision equipment identifies these issues early, reducing the risk of rework.

3. Maintain Process Stability

Measurement data allows operators to adjust press parameters and production methods in real-time, maintaining consistent quality across batches.

4. Ensure Compliance with Industry Standards

Many industries, including automotive and medical devices, require compliance with ISO and industry-specific standards. Precision measurement ensures parts consistently meet these standards.

5. Improves Operational Efficiency

Faster and more accurate inspections reduce downtime and improve throughput, allowing manufacturers to meet tight production schedules.

Manufacturers rely on specialized equipment to maintain high quality standards. Key tools include:

Coordinate Measuring Machines (CMM)

Provides micron-level accuracy for measuring complex geometries, angles, and hole positions.

Ensures parts match CAD designs exactly.

Widely used for critical components such as automotive engine brackets, medical instruments, and precision connectors.

Video Measuring Systems (VMS)

Non-contact optical systems for inspecting thin, small, or delicate parts.

Reduces measurement errors caused by manual methods.

Ideal for high-volume production lines where speed and accuracy are both critical.

3D Scanners

Captures complete surface profiles and complex geometries in three dimensions.

Compares stamped parts to CAD models, detecting warping, springback, or subtle deviations.

Especially useful for parts with intricate shapes or curves that are difficult to measure with traditional tools.

By combining these technologies, manufacturers can achieve faster, more accurate inspections, improving both part quality and overall production efficiency.

How Precision Measurement Enhances Metal Stamping Production

1. Reduces Scrap and Material Waste

Early detection of deviations prevents large batches of defective parts, lowering material costs.

2. Shorten Production Cycles

Fast and accurate inspections allow operators to adjust processes quickly, minimizing downtime and maintaining throughput.

3. Extends Production Cycles

Monitoring wear on punches and dies helps prevent overuse or damage, reducing tool replacement costs.

4. Support Continuous Improvement

Measurement data can be analyzed to identify trends, helping manufacturers refine press parameters, material handling, and workflow processes over time.

5. Improves Product Reliability and Customer Satisfaction

Consistently delivering high-quality parts strengthens client trust and minimizes warranty or assembly issues.

6. Enhances Competitiveness

Manufacturers using high-precision measurement gain a competitive edge by reducing production errors, improving efficiency, and delivering consistent quality.

Applications Across Industries

High-precision measurement is widely applied across multiple sectors. In the automotive industry, engine brackets, chassis components, and connectors require tight tolerances to ensure vehicle performance and safety. Medical devices, such as surgical tools and implants, demand exact precision to meet strict quality standards and ensure patient safety. Consumer electronics benefit from careful inspection of thin metal casings, frames, and connectors to maintain both functionality and aesthetics. Industrial machinery uses precision measurement to verify complex stamped components, ensuring proper fit, reducing assembly errors, and minimizing downtime. By adopting high-precision measurement across these industries, manufacturers can consistently deliver high-quality, reliable, and efficient products.

Conclusion

Achieving high-quality stamped metal parts relies on precision, consistency, and careful process management. By monitoring production, identifying issues early, and maintaining tight tolerances, manufacturers can reduce waste, lower costs, and improve product reliability.

Consistently high-quality parts reduce assembly errors, enhance operational performance, and build customer trust and satisfaction. Focusing on quality and continuous improvement also supports efficient workflows, timely production, and long-term competitiveness.

In today’s fast-paced manufacturing environment, companies that prioritize accuracy, quality, and continuous improvement can deliver superior products, strengthen their reputation, and achieve sustainable success.