Medical devices must meet the highest standards of quality and reliability. A minor defect in a surgical instrument, implant, or catheter can endanger patient safety and trigger costly recalls. This is why precision inspection is not optional it is a core requirement in medical device manufacturing.

Advanced inspection technologies provide manufacturers with accurate, repeatable, and traceable results. They ensure that every device meets strict international regulations while enabling faster, more efficient production.

This article explores why precision inspection matters, the technologies involved, key applications, and the benefits for medical device manufacturers.

Why Precision Inspection Matters in Medical Device Manufacturing

From implants and pacemakers to surgical tools and catheters, every product that reaches a patient must perform flawlessly. Even a micron-level defect in dimensions, surface finish, or internal structure can compromise safety and lead to costly recalls.

Precision inspection ensures that:

Devices meet strict design tolerances

Surfaces are free from cracks or irregularities

Internal assemblies remain intact and defect-free

This level of control protects patients and gives healthcare providers confidence in the devices they use.

Meeting Global Standards and Regulations

Regulatory frameworks such as ISO 13485, FDA 21 CFR, and CE certification require strict quality control. Inspection systems support compliance by providing:

Traceable measurement data for audits

Automated reports for validation and certification

Reliable quality records that prevent costly recalls

Hansvue’s inspection technologies help manufacturers stay compliant while maintaining efficiency in production

Industry Challenges Driving Precision Inspection

Medical device manufacturing faces unique challenges that demand tighter inspection controls:

Miniaturization: Devices such as micro-needles, stents, and sensors are shrinking to micro and nano scales, where traditional inspection methods fall short.

Complex Materials: Increasing use of composites, polymers, and bio-compatible coatings requires advanced imaging to verify structural and surface quality.

Rising Regulatory Scrutiny: Authorities are tightening guidelines, requiring more detailed traceability and validation throughout the production cycle.

Global Supply Chains: With parts sourced worldwide, consistent quality assurance becomes essential to avoid variability in final assemblies.

Precision inspection addresses these challenges by delivering accuracy, repeatability, and documentation that stand up to both engineering and regulatory demands.

Advanced Inspection Technologies in Medical Devices

Different types of devices require different inspection solutions. Hansvue offers systems tailored to each challenge:

X-Ray and CT Inspection

Non-destructive imaging of internal structures

Detects voids, cracks, misalignments, or trapped air in assemblies

Ideal for catheters, pacemakers, and sealed devices

Scanning Electron Microscopy (SEM)

Ultra-high magnification for micro and nano features

Evaluates surface finishes, micro-needles, stents, and coatings

Used in both R&D and failure analysis

CMM and Optical Measurement

Verifies dimensions of implants, surgical instruments, and complex geometries

Ensures accuracy and repeatability in mass production

Applications Across Medical Device Manufacturing

Precision inspection is applied at multiple stages of production, including:

Orthopaedic and Dental Implants: Dimensional checks, surface roughness, structural integrity

Cardiovascular Devices: Stents, catheters, and pacemakers inspected for micro-scale defects and internal reliability

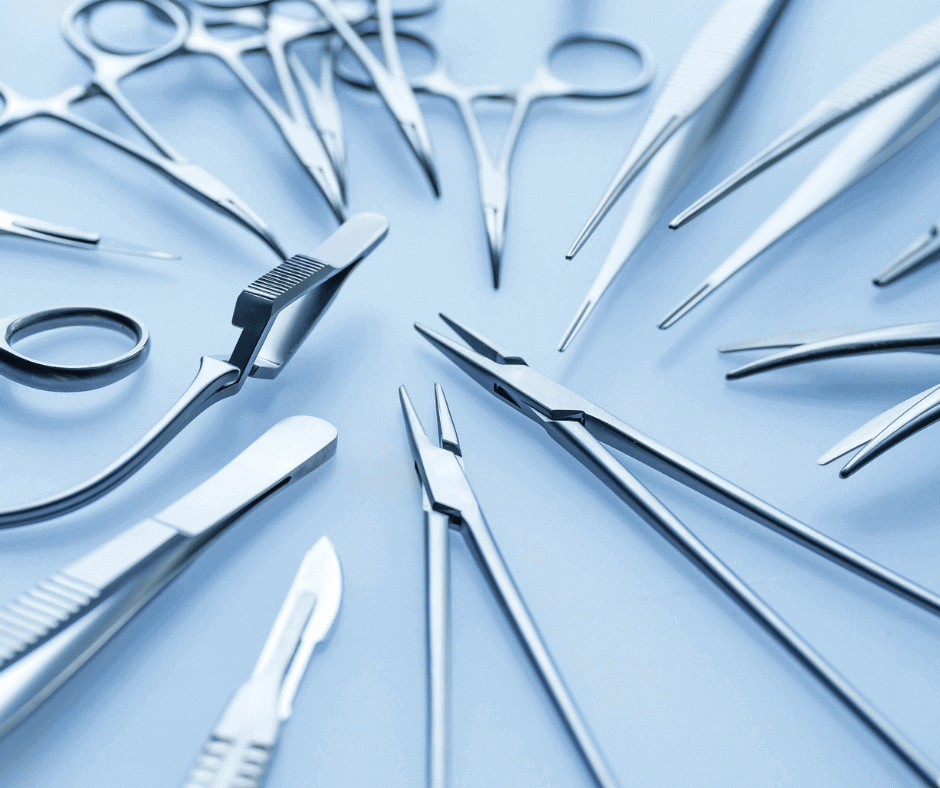

Surgical Instruments: Sharpness, geometry, and repeatability verified for consistent performance

Drug Delivery Systems: Micro-needles and coating analysis at nano-scale precision

Benefits for Manufacturers

Implementing precision inspection brings clear advantages:

- Safety First: Eliminates the risk of defective products reaching patients

- Efficiency: Automated, high-throughput inspection reduces delays

- Cost Savings: Early defect detection minimizes rework, scrap, and recalls

- Regulatory Confidence: Full traceability for global audits and certifications

- Market Trust: High-quality devices strengthen brand reputation and customer loyal

Conclusion

Precision inspection is not just a step in medical device production it is the foundation of safety, compliance, and innovation. It ensures implants, surgical tools, and life-saving devices meet the tightest tolerances, comply with global regulations, and most importantly, protect patients.

By delivering advanced inspection systems such as X-Ray CT, SEM, CMM, and optical solutions, Hansvue Metrology helps manufacturers achieve accuracy, repeatability, and traceability in every device they produce.

With precision inspection built into production, the medical device industry can deliver safer, more reliable, and more innovative solutions—devices that healthcare providers trust and patients depend on.