DESCRIPTION

UNT X-ray Intelligent Inspection System for specialized power industry applications. Primary Applications: Defect detection in high-voltage switch insulators (Insulating spacers, insulating bushings, epoxy pull rods, support insulators, contact seats, grounding bases) Flaw inspection in insulating resin components (Internal inclusions, cracks, bubbles) Bonding integrity analysis of metal-insulator composites Key Feature: A high-efficiency, fully automated inline inspection solution for industrial quality control.

Equipment Features

- Functions: Specifically designed for small/micro product inspection with high intergration design, comprehensive functionality and compact structure

- Safety: High grade protection, radiation is far below the nation standard. Set up with multiple safety measures

- Operation: Equipped with a power indsutry applications radiography system, it deivers superior image clarity under precision-engineered conditions

- High Detection Efficiency: Directly intergrated into prodcution lines for high-speed CNC in-line detection

Inspection Images

Inspection picture are highly visible and can visually show the existence of bubbles, cracks, impurities, loose and other internal defects in casting products

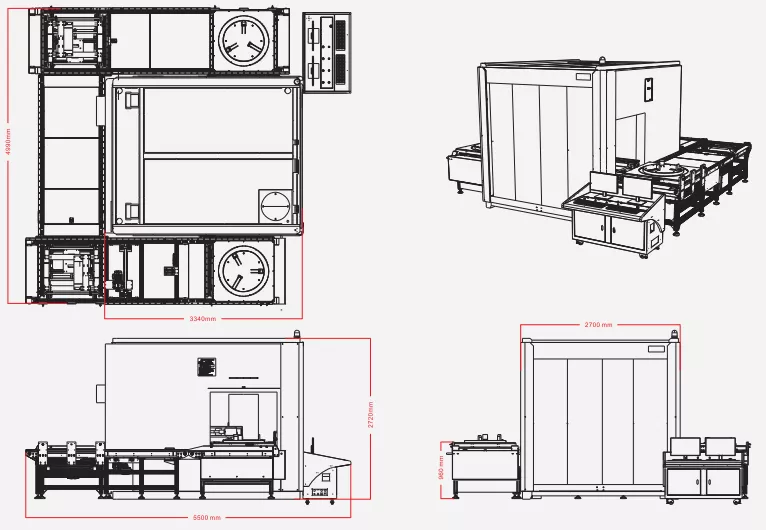

Dimensions and Appearance