Quality control is the backbone of modern manufacturing. A minor dimensional error in a component can lead to assembly issues, product malfunctions, or costly recalls. Traditional tools such as calipers and micrometers remain valuable, but they cannot always meet the speed, accuracy, and complexity demands of today’s production environments.

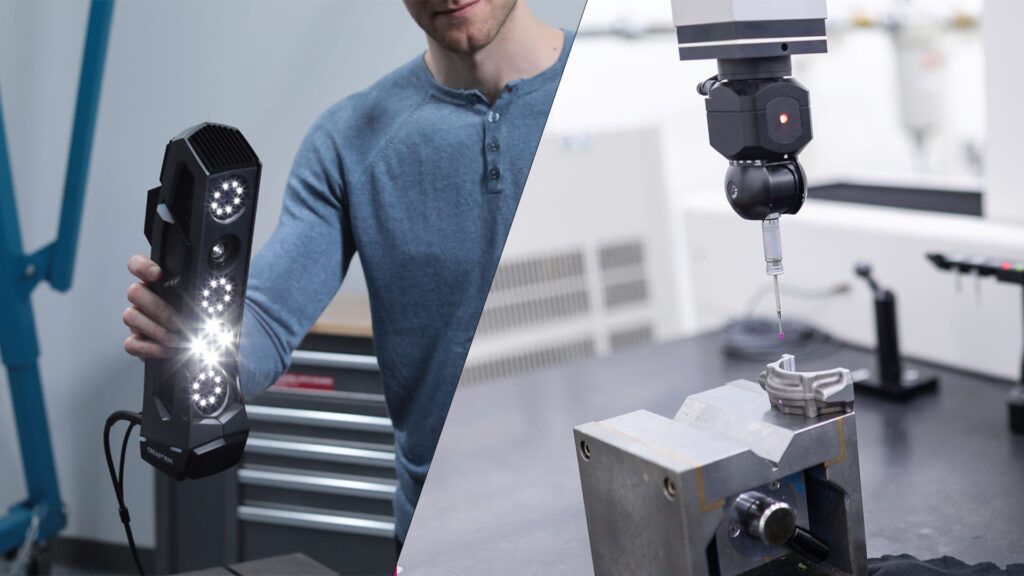

To address these challenges, manufacturers rely on two primary measurement approaches: contact measurement and non-contact measurement. Each method offers distinct advantages, limitations, and ideal applications depending on the material, geometry, and inspection requirements.

This article explains the principles of both methods, compares their strengths and drawbacks, and highlights how they are applied across industries to maintain precision and efficiency in quality control.

What is Contact Measurement?

Contact measurement uses a physical probe or stylus that touches the surface of the workpiece to capture dimensions. Examples include micrometers, calipers, and coordinate measuring machines (CMMs) with tactile probes.

Provides highly reliable and repeatable results.

Suitable for checking critical tolerances on machined parts.

Effective even in harsh shop-floor environments.

However, the probing process can be slower, and delicate surfaces risk being scratched or deformed.

Types of Contact Measurement:

- Coordinate Measuring Machines (CMMs): Use a probing system to measure precise 3D dimensions.

Micrometers and Calipers: Common handheld tools for quick, accurate linear measurements.

Dial Indicators: Used for alignment, flatness, and runout checks.

Surface Roughness Testers: Employ a stylus to trace the surface profile.

What is Non-Contact Measurement?

Non-contact measurement uses technologies such as optical sensors, lasers, or vision systems to capture part geometry without touching it.

Captures multiple data points rapidly.

Ideal for complex geometries, soft materials, or fragile components.

Eliminates risk of surface damage.

The trade-off is sensitivity to environmental conditions such as lighting, dust, or reflectivity, which can affect accuracy if not managed properly.

Types of Non-Contact Measurement:

- Optical Systems (Vision Measurement): Use cameras and lenses to capture dimensions and surface features.

Laser Scanners: Sweep a laser beam across the surface to collect 3D data.

White Light/Confocal Sensors: Provide high-resolution surface profiling.

X-Ray or CT Scanning: Generate internal images of components for defect detection and dimensional analysis.

Advantages and Disadvantages

Contact Measurement

Advantages:

Micron-level accuracy.

Consistent results on hard surfaces.

Less sensitive to lighting and environment.

Disadvantages:

Slower inspection speed.

Limited access to hidden or complex geometries.

Wear and tear on probes increases maintenance costs.

Non-Contact Measurement

Advantages:

- High-speed inspection.

Capable of measuring fragile, soft, or hot materials safely.

Effective for complex 3D profiles.

Disadvantages:

Sensitive to vibrations, lighting, and reflectivity.

Higher initial investment.

Requires skilled setup and calibration.

Key Differences Between Contact and Non-Contact Measurement

Aspect | Contact Measurement | Non-Contact Measurement |

Measurement Method | Probe touches part surface | Sensors capture data remotely |

Accuracy | Very high (micron-level) | High to moderate, depending on sensor technology |

Speed | Slower, point-by-point | Faster, captures entire surfaces or profiles |

Surface Sensitivity | Can damage delicate parts | Safe for fragile or deformable materials |

Geometry Handling | Limited to accessible areas | Excellent for complex and hidden features |

Environment Sensitivity | Low impact from dust or light | Sensitive to dust, light, vibration |

Cost | Lower equipment cost, higher labor | Higher initial cost, faster ROI in automation |

Maintenance | Probe tips wear out | Optics need cleaning, alignment required |

Typical Applications | Precision machining, toolmaking, harsh environments | Electronics, aerospace, medical, high-volume inspection |

Best Uses in Quality Control

Contact Measurement is best for:

- Small production batches.

Ultra-precise machining.

Applications where environmental stability is critical.

Non-Contact Measurement is best for:

- High-speed, high-volume production lines.

Parts with fragile, polished, or soft surfaces.

Complex 3D shapes requiring complete surface analysis.

Choosing the Right Method

- Selecting between contact and non-contact measurement depends on several key factors:

Material Properties

- Contact methods are reliable for hard, rigid materials that can withstand probe pressure without deformation.

- Non-contact methods are better for delicate, flexible, or soft surfaces that may be scratched, compressed, or altered by a probe.

Geometry and Size

- Contact measurement works well for simple shapes, flat surfaces, and parts with accessible features.

- Non-contact measurement excels at complex geometries, small components, or parts with deep grooves and difficult-to-reach areas.

Speed and Throughput

- For high-volume production lines, non-contact systems provide faster inspection, enabling real-time quality monitoring.

- Contact methods are more suitable for low-volume or high-precision checks where speed is less critical.

Accuracy and Resolution

- Both methods can deliver high accuracy, but contact systems are often preferred when absolute dimensional accuracy is required.

- Non-contact systems offer advantages when measuring micro-features, surface profiles, or dynamic movements.

Industry Application

- Automotive, aerospace, and heavy industries often rely on contact systems for robust, high-precision checks.

- Electronics, medical devices, and semiconductor sectors lean towards non–contact methods to handle miniaturized, fragile, or complex components.

In practice, many manufacturers use a hybrid approach, combining both methods to balance speed, precision, and adaptability. For example, a company may use contact gauges for dimensional checks of machined parts, while deploying non-contact optical systems for surface inspection and final verification.

6. Conclusion

Selecting between contact and non-contact measurement comes down to aligning each method’s strengths with the specific requirements of the product and process. Both approaches are essential in modern manufacturing, ensuring accuracy, quality, and reliability.

Contact measurement is valued for its direct touch accuracy, stability, and suitability for parts requiring highly precise dimensional verification. It remains the standard in industries such as automotive, aerospace, and heavy machinery, where durability and tight tolerances are critical.

Non-contact measurement excels in speed, flexibility, and the ability to inspect delicate, miniaturized, or complex surfaces without causing damage. It is widely used in electronics, medical devices, and high-volume production environments where rapid, repeatable results are essential.

By understanding the core advantages of each approach and applying them to the right context, manufacturers can create a balanced quality control strategy that improves efficiency, reduces errors, and ensures consistent product performance.