Precision measurement is essential in modern manufacturing. Even the smallest deviation can result in poor product quality, production delays, or costly rework. While traditional measuring tools like calipers and gauges remain reliable, they can no longer keep up with the speed, complexity, and accuracy requirements of today’s advanced production lines.

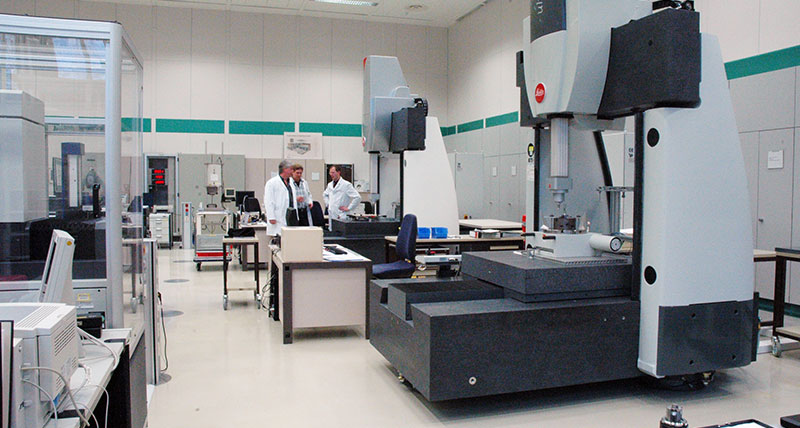

Advanced metrology solutions such as Coordinate Measuring Machines (CMM) and Vision Measuring Machines (VMM), also known as Vision Measuring Systems (VMS), have transformed how industries handle dimensional inspection. These systems deliver the high-precision measurements needed for complex geometries, fine tolerances, and critical quality control. Both are powerful technologies, yet each excels in different scenarios and offers unique advantages.

This article explores the key differences between CMM and VMM, their respective benefits, and how manufacturers can select the right solution to enhance measurement accuracy, improve efficiency, and maintain consistent product quality.

1. Coordinate Measuring Machine (CMM)

Coordinate Measuring Machines (CMM) are precision instruments that use a contact probe to collect accurate 3D coordinates from a part’s surface. CMMs are designed for measuring complex geometries, large components, and parts that require tight tolerances.

The probe either touch-trigger or scanning moves along the X, Y, and Z axes to capture detailed dimensional data. This data is processed by metrology software to analyze features such as planes, cylinders, spheres, and contours.

CMM technology delivers high accuracy for industries such as automotive (engine blocks, gearboxes), aerospace (turbine blades, fuselage parts), and tool & die manufacturing (molds, jigs, fixtures). CMM is widely valued for versatility, repeatable measurements, and the ability to verify parts against CAD models.

Key Advantages of CMM:

Accurate 3D measurements for complex geometries

Handles large and heavy parts with ease

Ideal for tight tolerance manufacturing

Flexible for metals, plastics, composites, and more

Common Uses for CMM:

Automotive: engine blocks, gearboxes, brake components

Aerospace: turbine blades, fuselage parts

Tool & Die: molds, jigs, fixtures

Heavy Machinery: industrial gears, shafts

Key Applications

Manufacturers dealing with large or complex parts where 3D accuracy is critical.

2. Vision Measuring System (VMS)

Vision Measuring Systems (VMS), also known as Video Measuring Machines (VMM) or Image Measuring Systems, are optical instruments for precise measurement of small, delicate, or intricate parts. Using a non-contact method, VMS avoids damage to sensitive components during inspection.

The visual sensor made up of a high-resolution camera and optical lens is the core of the system. Some setups also include laser probes for measuring transparent or translucent materials and contact probes for obtaining precise 3D distance data.

VMS captures high-quality images of a part and processes them with computer software to create a detailed model. From this, operators measure linear attributes (points, lines, angles) and geometric attributes (radii, diameters, contours). VMS is widely used in electronics, medical devices, and precision engineering for its accuracy, repeatability, and fast, non-contact inspection.

Key Advantages of VMS:

Non-contact measurement — no risk of damage

Extremely fast for 2D inspections

Perfect for small, delicate, and intricate components

High repeatability for batch QC

Common Uses for CMM:

Electronics & Semiconductors: PCB boards, microchips

Medical Devices: surgical tools, stents, implants

Precision Engineering: watch parts, fine tooling

Plastics: injection-molded components

Key Applications

Manufacturers producing small, fragile, or micro-scale parts that require fast and precise inspection.

3. CMM vs VMS: Understanding the Key Differences

Both Vision Measuring Machines (VMM) also called Vision Measuring Systems (VMS) And Coordinate Measuring Machines (CMM) measure an object’s geometric features with high precision. However, the way they operate, the parts they suit best, and their ideal applications are very different. Let’s break down the main differences.

Feature / Factor | VMM (Vision Measuring Machine) | CMM (Coordinate Measuring Machine) |

Measuring Method | Non-contact optical measurement using cameras, laser probes, and imaging software. | Contact measurement using mechanical probes to capture 3D coordinates. |

Speed | Very fast for 2D and profile measurements; ideal for high-volume inspections. | Slower, as the probe collects point-by-point data, especially for complex geometries. |

Accuracy | Ultra-precise for 2D—down to 0.25 microns. | High accuracy for 3D—typically 2 to 5 microns. |

Applications | Electronics, semiconductors, medical devices, and small precision parts. | Automotive, aerospace, molds, fixtures, and large or heavy components. |

Cost & Maintenance | Lower cost, easy maintenance, fewer moving parts. | Higher initial cost, requires more maintenance due to moving mechanical components and calibration needs |

When deciding between a Vision Measuring Machine (VMM) and a Coordinate Measuring Machine (CMM), keep these factors in mind:

Workshop Size – Limited space? A VMM’s compact footprint makes it a better fit.

Inspection Volume – Need to check hundreds of small parts daily? VMM is faster. For fewer, larger, or more complex parts, CMM is better.

Measurement Type – VMM is perfect for high-precision 2D measurements; CMM is built for detailed 3D analysis.

Accuracy Needs – VMM can reach 0.25-micron accuracy; CMM typically delivers 2–5 microns in 3D.

Part Fragility – Non-contact VMM protects delicate or deformable materials from probe pressure.

4. Conclusion

Selecting between a Coordinate Measuring Machine (CMM) and a Vision Measuring System (VMS) comes down to aligning each system’s unique strengths with the specific needs of the manufacturing process. Both are high-performance precision instruments capable of enhancing quality control, improving measurement accuracy, and boosting production efficiency.

VMS stands out for its speed, non-contact inspection, and exceptional precision when measuring small, delicate, or intricate components. This makes it an excellent choice for industries such as electronics, medical devices, and precision engineering, where high throughput and repeatability are essential.

CMM delivers unmatched versatility for large, heavy, or geometrically complex parts that require accurate 3D measurements. Its ability to work with a wide range of materials and verify parts directly against CAD models makes it ideal for automotive, aerospace, and tool & die applications.

By understanding the core capabilities of each system and matching them to production requirements, manufacturers can confidently choose the solution that ensures consistent quality, reduces waste, and supports long-term operational success.