X-ray inspection has become an essential part of non-destructive testing (NDT) in industries such as electronics, automotive, aerospace, and medical devices. As products become smaller, more complex, and more precise, manufacturers need reliable ways to detect hidden defects without damaging the item.

Two of the most common techniques are 2D X-ray inspection and 3D X-ray inspection. Both methods use X-rays to reveal internal structures, but they differ in the type of image they produce, the level of detail they provide, and the situations where they are most effective.

In this article, we will break down the differences between 2D and 3D X-ray inspection, discuss their applications, and help you understand which method suits your needs.

What is 2D X-Ray Inspection?

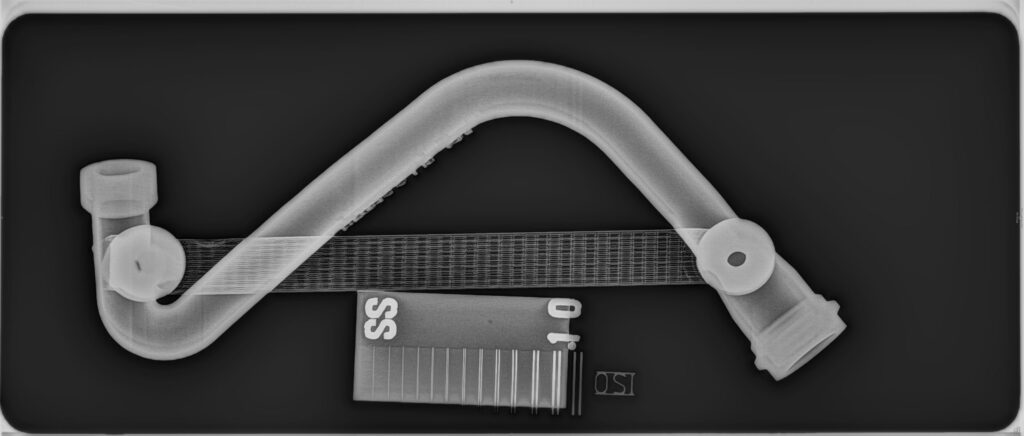

2D X-ray inspection, also called digital radiography, is the traditional method. It works by projecting X-rays through an object and capturing the resulting shadow image on a flat detector. The darker areas represent denser materials, while lighter areas show less dense regions..

Advantages of 2D X-Ray Inspection:

- Fast throughput: Ideal for high-volume production lines where speed is crucial.

-

Cost-efficient: Equipment and running costs are significantly lower than 3D systems.

-

Ease of use: Simple image capture and analysis, often with minimal operator training.

-

Reliable for basic defects: Good for detecting cracks, missing parts, solder bridges, and large voids.

Limitations:

- Overlapping structures: Hidden or layered parts may obscure defects.

No depth information: Cannot determine the exact position of a defect inside the object.

Lower precision: Not suitable for highly complex or safety-critical inspections.

Common Applications:

- Electronics manufacturing: Inspecting solder joints on printed circuit boards (PCBs).

Automotive: Checking castings for porosity, cracks, and inclusions.

Metal fabrication: Detecting weld defects.

Packaging: Inspecting for contamination in food and pharmaceutical products.

What is 3D X-Ray Inspection?

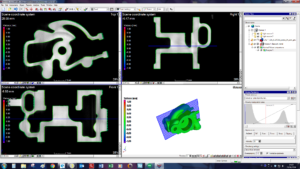

3D X-ray inspection, also known as computed tomography (CT) scanning, takes X-ray imaging further. Instead of one flat projection, it captures multiple 2D images from different angles. These images are then reconstructed into a 3D volumetric model, allowing users to examine the inside of a part in detail.

Advantages of 2D X-Ray Inspection:

- Full internal visibility: Provides cross-sectional views without physically cutting the part.

Precise measurements: Allows accurate dimensional analysis of internal and external features.

Better defect detection: Identifies cracks, voids, or misalignments that may be hidden in 2D images.

Versatility: Useful for both production and research applications.

Limitations:

- Slower inspection speed: Scanning and reconstruction take more time than 2D imaging.

Higher cost: Equipment and maintenance are more expensive.

Requires skilled operators: Image analysis and interpretation are more complex.

Common Applications

- R&D and prototyping: Verifying new product designs before mass production.

Medical device manufacturing: Checking implants and surgical instruments for reliability.

Aerospace and defense: Inspecting turbine blades, composites, and safety-critical structures.

Complex electronics: Analyzing multilayer PCBs and high-density interconnects.

Key Differences Between 2D and 3D X-Ray Inspection

|

Feature |

3D X-Ray Inspection |

3D X-Ray Inspection |

|

Image Output |

Flat, two-dimensional image |

Volumetric, 3D reconstruction |

|

Visibility of Defects |

Limited by overlapping structures |

Clear internal cross-sections |

|

Speed |

Very fast |

Slower, due to multiple scans |

|

Cost |

Lower investment and running cost |

Higher initial and operating cost |

|

Accuracy |

Adequate for simple defects |

R&D, failure analysis, critical parts |

|

Best Use |

Routine, high-volume inspection |

Sensitive to dust, light, vibration |

Choosing Between 2D and 3D X-Ray Inspection

The decision depends on the balance between cost, speed, and required accuracy:

Choose 2D when:

- You need fast inspection for high-volume products.

- Parts are relatively simple with minimal overlap.

- Budget is limited, but consistent quality checks are needed.

Choose 3D when:

- You require detailed analysis of internal structures.

- Your components are complex with overlapping features.

- You are conducting failure analysis, research, or prototyping.

Some companies even use a hybrid approach: applying 2D X-ray inspection for routine checks and switching to 3D X-ray inspection for deeper investigations.

Future of X-Ray Inspection in Industry

With the rise of Industry 4.0 and smart factories, X-ray inspection is evolving rapidly:

Automation and AI integration: Automated defect recognition (ADR) is reducing human error and speeding up inspections.

Real-time data analysis: Results can be directly linked to manufacturing systems for faster decision-making.

Faster 3D imaging: Technological advances are reducing scanning times, making 3D inspection more practical for production lines.

Miniaturization of components: As electronics become smaller and denser, demand for advanced X-ray inspection will continue to grow.

6. Conclusion

2D and 3D X-ray inspection are both vital tools in non-destructive testing, but they address different needs. The 2D method is valued for its speed and lower cost, making it ideal for high-volume production and routine inspections where simple defects need to be identified quickly. In contrast, 3D inspection provides a more detailed and accurate view of internal structures, which is essential when dealing with complex assemblies, critical components, or failure analysis. Many industries now combine both methods using 2D for rapid checks and 3D for in-depth analysis to achieve a balance between efficiency, accuracy, and cost. As technology continues to advance, these two approaches will remain complementary, ensuring manufacturers can maintain high standards of quality, safety, and performance.